小编:落萧

在射线的检测中,裂纹是最难被检出的。那么在使用TTRT的检测手段时,是否也存在裂纹难以检出的难题呢?

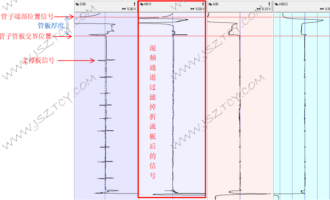

经过这些年使用TTRT检测手段来检测管板角焊缝,我也学到很多新的知识。对这项技术也有新的认识和理解。在常规射线检测中会有一个缺陷检出率的概念,包括裂纹的检出率。虽然管板角焊缝射线检测并没有这些数据。但是我从工作中也遇到很多实例证明,角焊缝的裂纹,TTRT确实能很好的检出。例如18年在某化肥厂,厂里关键设备停运,导致整个装置无法运行。而致使设备停运的关键就是管板角焊缝的泄漏。于是厂家找到我们,准备用TTRT检测查出到底是什么缺陷导致的角焊缝泄露。

在实施完检测后发现很多的贯穿裂纹,当时看来觉得完全不可思议。因为在底片上显示,每个管头存在多处贯穿性裂纹。而且拍的每个管头,基本都是这样的情况。所以当时决定打磨几个管头,以此来确定一下检测结果的准确性。首先在底片上确定了裂纹的位置,然后用打磨机慢慢的把焊肉一点点磨掉。再用渗透检测来检测是否真的是这么多裂纹存在。经过几次打磨渗透检测后,可以确定实际的裂纹缺陷和底片完全吻合。至此,厂方对我们TTRT检测技术完全信服。通过这次检测也帮他们找到了问题所在,进而帮助他们把问题解决。其实作为我们检测人员来讲,能真正的帮助客户解决问题,也是我们发自内心的高兴。

发表评论