小编:與龍共舞

IRIS is an ultrasonic method used for the non-destructive testing of pipes and tubes.

内旋转超声检测系统是一种用于管道和管材无损检测的超声波检测方法。

Many plant operators in the oil, gas and power generation industries are faced with the challenges of maximising the efficiency and life expectancy of their assets but without sacrificing safety and reliability. Therefore accurate inspection of vital components such as pipes and tubes is crucial to ensuring the integrity of the plant. IRIS detection technology can solve this problem.

许多石油石化、天然气和发电行业等企业都面临这一个问题,如何在不牺牲安全性和可靠性的情况下最大限度地提高其设备的使用效率和寿命。因此,准时准确的了解管道和管道等重要部件的实时状况,对于确保工厂设备的完整性至关重要。

Internal Rotary Inspection System (IRIS) can detect corrosion, pitting and wall loss and is most commonly used for tube inspection in boilers, heat exchangers, air coolers and feed water heaters. It is particularly versatile as it is suitable for both ferrous and non-ferrous materials, and IRIS can be used on a wide range of tube diameters and wall thicknesses.

内部旋转检测系统 (IRIS) 可以检测腐蚀、点蚀和壁厚损失,最常用于锅炉、热交换器、空气冷却器和管式反应器等的管束检测。该技术通用性强,它几乎适用于各种材质金属材料,而且适用管径和壁厚范围也很广。

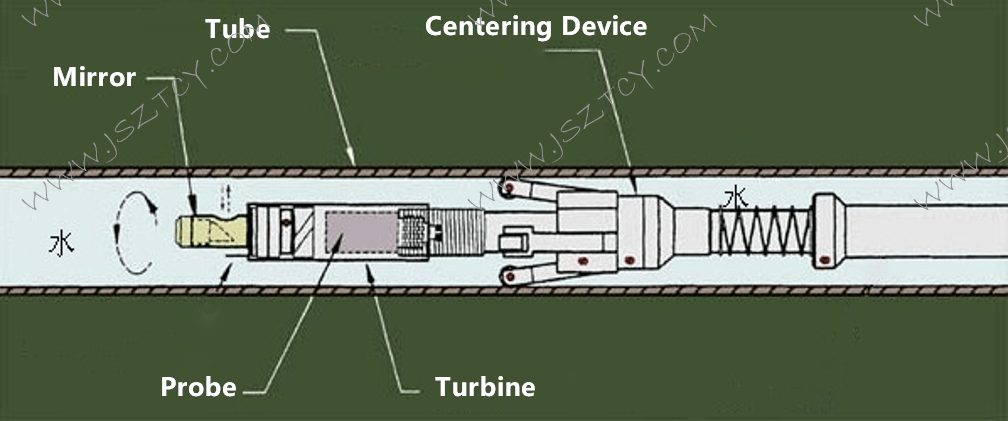

An IRIS probe is inserted into a tube flooded with water. The probe is fitted with a transducer that generates an ultrasonic pulse along a path parallel to the axis of the tube. A rotating mirror directs the ultrasonic pulse into the tube wall. The mirror is driven by a small turbine that is rotated by the pressure of water pumped into the tube.

将IRIS探头插入充满水的管中,探头配有一个换能器,该换能器沿平行于管子轴向方向产生超声波脉冲。45°旋转反射镜将超声波脉冲反射到管壁中,反射镜子由一个小型水涡轮机驱动,该水涡轮机通过泵入探头中的水的压力旋转。

The ultrasound pulses are reflected by the inner-diameter (ID) wall and outer-diameter (OD) wall of the tube and the time of flight difference between the two diameters is used to calculate the wall’s thickness.

超声波脉冲被管的内壁(ID)和外壁(OD)反射接收,计算内外径之间的时间可得出管厚度。

As the IRIS probe is pulled, the spinning motion of the mirror results in a helical scan path ensuring full coverage of the tube.

反射镜持续转动,当IRIS探头被拉动时,反射镜子的旋转运动会产生螺旋扫描路径,确保管子的检测完全覆盖。

Benefits of using IRIS include:

使用IRIS检测的好处:

Suitability for ferrous and non-ferrous materials

使用于所有黑色金属和有色金属材料

Detection of corrosion, pitting and wall loss

可准确检测腐蚀、点蚀和壁厚

Accurate wall thickness measurements

拥有高精度的壁厚测量值(0.03mm)

Sensitivity to both internal and external defects

对内部和外部缺陷都非常敏感

Defect position can be located in relation to tube length

可精确定位缺陷在管子长度方向的位置

100% coverage of the tube

管子100%全覆盖检测

Results data storage

所有结果数据存储

Flexibility as a back-up to remote field, magnetic flux leakage and eddy current inspections

可和配合涡流、内窥镜做精确的多方位检测

Our NDT inspectors have years of experience using IRIS and they can provide you with an accurate assessment of the condition of your assets and Total Quality Assurance.

我们的无损检测人员拥有多年的IRIS使用经验,他们可以为您的设备提供准确的评估和全面的质量保证。